What custom make & break solutions does Wil-Tech offer?

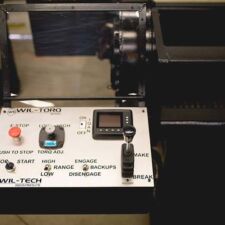

WIL-TORQ GENERATION 3

The WIL-TORQ G3 is our latest evolution in a line of hydraulic bucking units that are field proven, durable work horses with a trusted reputation based on years of work through the toughest conditions imaginable for a piece of equipment.

The G3 is driven by hydraulic power unit contained in a compact frame system that supports the hydraulically driven head. The drive head’s jaws grip the tubular’s coupling while a non-rotating backup assembly slide to the desired length and grip the body of the tubular at the optimum distance from the collar.

The WIL-TORQ G3 is user-friendly and requires minimal maintenance making it ideal for shop and field operations for completion, oil tool inspection and oil tool companies. Some of the reasons our client’s choose the G3:

- CUSTOMIZABLE BUCKING UNIT

- SELF-CONTAINED UNIT ON A COMPACT FRAME

- SUITABLE FOR INDOOR AND OUTDOOR USE

- ELECTRIC AND DIESEL MODELS AVAILABLE

- PIPE SIZES RANGING FROM 2-3/8” TO 6-/16” OD

- TWO SPEED OPERATION WITH MAX SPEED (HIGH GEAR) 76 RPM

- WIL-TORQ TORQUE MONITORING & REPORTING SYSTEM

- BACKUP MOUNTED ON 6′ – 10’ SLIDE

WIL-TORQ GENERATION 2

Wil-Tech manufactures the WIL-TORQ G2, a modular hydraulic pipe bucking unit, available in both electric and diesel powered version capable of upwards of 16000-foot pounds of torque. Redesigned from the ground up, the G2 has been engineered for adaptability; the advanced G2 model offers more flexible power options and can be extended up to 24’ with a variety of extensions that are engineered to affix to one another at the ends. With its module design and pleasing aesthetic design, any factory floor would be proud to house one of the units.

WIL-TORQ control console that includes the PC running the state of the art IQAN torque monitoring system extends functionality. The control console stores logs and produces branded PDF reports of each job and pipe joint it torques and incorporates a keyboard, mouse and display screen for entering job data, and monitoring torque on screen in real time.

- SELF CONTAINED UNIT ON A COMPACT FRAME

- SUITABLE FROM INDOOR AND OUTDOOR USE

- ELECTRIC AND DIESEL MODELS

- INCLUDES FLOOR ANCHORING HARDWARE

- ENGINEERED MODULAR DESIGN

- EXTENSIONS AVAILABLE IN 8’, 16’, 24’ LENGTHS

- PIPE SIZES RANGING FROM 2-3/8” TO 6-/16” OD

- MAX. TORQUE (LOW GEAR) 16000 FT-LB

- TWO SPEED OPERATION WITH MAX SPEED (HIGH GEAR) 76 RPM

- STANDALONE CONTROL CONSOLE WITH WIL-TORQ TORQUE MONITORING & REPORTING SYSTEM

- STANDALONE HYDRAULIC POWER UNIT

- BACKUP MOUNTED ON 8’ SLIDE

WIL-TORQ Generation 1

Wil-Tech manufactures the WIL-TORQ G1, a self-contained pipe bucking unit, as 11000 and 16000 ft-lb versions. The unit’s compact frame and electric powered hydraulic power unit make it ideal for indoor operations. With a two speed gearbox it makes fast work of making and braking pipe connections: a maximum speed of 76 rpm in high gear; while in low gear it is capable of producing upwards 16,000 foot pounds of torque in both make and break connections.

The system comes complete with state of the art IQAN torque monitoring & reporting system that stores torque logs and produces branded PDF reports of each job and pipe joint it torques.

We are proud to say that there is no bucking unit quite like the WIL-TORQ G1. It may be a 1st generation design, but we believe these features are the reason our customers still gravitate to it.

- SELF-CONTAINED SKID UNIT

- ELECTRIC POWERED UNIT

- IDEAL FOR INDOOR USE

- SUITABLE FOR OUTDOOR

- PIPE SIZES RANGING FROM 2-3/8” TO 6-/16” OD

- MAX. TORQUE (LOW GEAR) 15000 FT-LB

- TWO SPEED OPERATION WITH MAX SPEED (HIGH GEAR) 76 RPM

- BACKUP MOUNTED ON 4’ SLIDE

- BUILT IN CONTROL CONSOLE WITH IQAN TORQUE MONITORING & REPORTING SYSTEM

- BACKED BY ONE YEAR WARRANTY

WIL-TORQ TORQUE MONITORING & REPORTING SOFTWARE

Wil-Tech developed WIL-TORQ Torque Monitoring & Reporting software application for retrofitting pipe tongs and bucking units that don’t have torque built in monitoring. We turn your old ‘dumb’ bucking unit, into old ‘smart’ an smart bucking unit.

The WIL-TORQ software is built on Parker’s IQAN controller, an excellent platform for customization to meet unique requirements of our clients.

The unit is extremely mobile; it can easily be tucked away in the cab of a truck until needed, then installed on the bucking unit or tong within minutes.

- CUSTOMIZABLE SOFTWARE SOLUTION

- PRODUCES PDF TORQUE REPORTS FOR EACH JOINT IN THE JOB

- SELF CONTAINED UNIT IN A COMPACT, DURABLE CASE

- USABLE FOR MULTIPLE TONGS & BUCKING UNITS

- AC/DC POWER SUPPLY OPTIONS

- INCLUDES REMOVABLE TABLET

- INCLUDES QUICK CONNECTORS FOR FAST INSTALLATION & REMOVAL OF SENSOR

- ADJUSTABLE VARIABLES TO ENABLE USE ON A VARIETY OF TONGS