Why choose Parker Transair over traditional pipework systems?

Safety

Transair has CRN numbers for most products across Canada.

Transair meets the requirements of ASME B31.3 and ASME B31.1 for non-boiler external piping which stipulates the minimum requirements for the design, materials, fabrication, erection, test, and inspection of piping systems for industrial plants.

Quick & Simple Installation

Transair components are lightweight, durable, and engineered for modularity; making them quick & easy to install and modify with minimal lightweight tooling required.

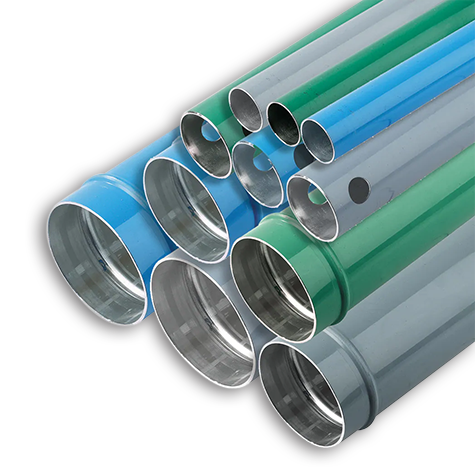

The Transair product line offers a complete range of diameters from [1/2?] to [6?], with adapted for all sections of your system.

Transair is 6 times lighter and faster to install than plastic, steel, stainless steel, or copper pipes. And best of all, Transair does not require welding or soldering so no hot work tickets required!

Air Quality

Transair has been successfully tested to the highest expectation of ISO 8573-1:2010 standard for air quality: class 1-1-1.

A Transair distribution network will not contaminate the fluid with solid particles, water, moisture, or oil.

Transair products are guaranteed Silicone Free, which is mandatory for premium air purity applications such as painting.

Range of Gases

Transair is suitable for compressed air applications (dry, lubricated, or with water condensation), for inert gas applications like nitrogen, argon, or CO2 (for purity up to 99.99%), and for vacuum applications (minimum vacuum level of 99% (29.6Hg).

Parker Transair Complete Pipe-to-Pipe Challenge

KEY ADVANTAGES OF PARKER TRANSAIR

Transair aluminum should be your 1st choice for compressed air, inert gases, and vacuum applications because you require:

TRANSAIR…

Strong

Lightweight

Modular

Corosion-Resistant

WHAT PARKER TRANSAIR & AIR PREPARATION (FRL) PRODUCTS DOES WIL-TECH OFFER?

ARE YOU DESIGNING AN INDUSTRIAL PIPING SYSTEM?

VISIT THE PARKER TRANSAIR TOOLS SITE FOR SOME HELPFUL DESIGN APPLICATIONS.